In cleanroom construction, panels are a critical component of the walls, ceilings, and sometimes floors, designed to meet strict contamination control and cleanliness standards. Here are the main types of cleanroom panels, categorized by material and construction type:

By Core Material

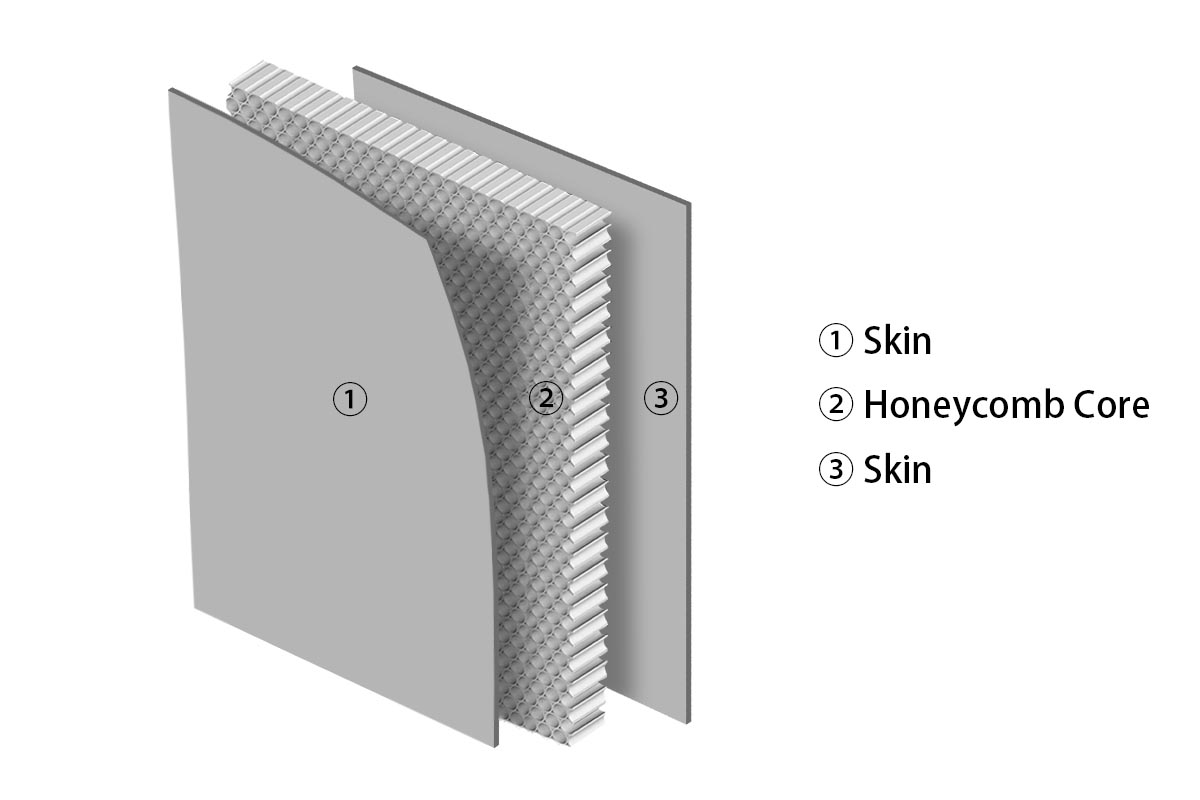

- Honeycomb Core Panels (Paneles de nido de abeja)

- Core made of aluminum or paper honeycomb.

- Lightweight, good rigidity.

- Common in modular cleanrooms.

- Fire resistant and low particle shedding.

- Rockwool (Stone wool – lana de roca) Core Panels

- Excellent fire resistance and sound insulation.

- Heavier than honeycomb.

- Good thermal insulation.

By Surface Finish

- Powder-Coated Steel / Pre-Painted Galvanized Iron (PPGI)

- Most common surface.

- Smooth, easy to clean.

- Antistatic and antibacterial options available.

- Stainless Steel Panels (SS304 or SS316)

- High resistance to corrosion and chemicals.

- Used in pharmaceutical, biotech, or high-humidity areas.

- More expensive but very durable.

- HPL (High-Pressure Laminate) Finish

- Durable, impact-resistant.

- Good for mechanical areas or corridors.

- PVC-Coated Panels

- Chemical-resistant.

- Often used in pharmaceutical or biotech cleanrooms.

🔹 By Panel Type

- Modular Cleanroom Panels

- Prefabricated and easy to assemble/disassemble.

- Ideal for projects with future modification needs.

- Clean finish, integrated with services (electrical, HVAC, etc.).

- Non-Modular / Traditional Drywall with Coating

- Gypsum board with epoxy or vinyl coating.

- More permanent, used in large-scale or fixed installations.

- More labor-intensive to install.

Special Types

- Antistatic Panels: For electronics manufacturing.

- Antibacterial Panels: For pharmaceutical and biotech.

- Glass Panels: For visibility in controlled environments.

- Walkable Ceiling Panels: Strong enough for maintenance access.

Selection Depends On:

- El sector Farmacautico tiende a usar rockwool y superficie Inoxidable / PPGI antibacteriano, sigue las normativas GMP y ISO 14644, suele ser mas caro y tiene como prioridad la limpieza, esterilidad y resistencia al fuego.

- El proyecto de Gigafactoria tiende a usar Honeycomb o Rockwool con superficie de PPGI antiestático o inoxidable, se rige por ISO 14644 (generalmente 7 y 8), tiene como prioridad ESD = ElectroStatic Discharge (en español, Descarga Electroestática) y resistencia al fuego.